Category

- Concrete Best Practices

The slump test is the most well-known and widely used test for concrete workability since 1922. This is mostly due to its simplicity, low cost, and immediate results. Widely standardized on a global scale, the Slump Test is regulated by ASTM C143 in the United States and EN 12350-2 in Europe.

This testing method consists of a cone with a base diameter of 8 inches, a top diameter of 4 inches, and a height of 12 inches. The cone is filled with concrete, and then removed. The shape of the concrete after the cone removal is then assessed to determine the workability.

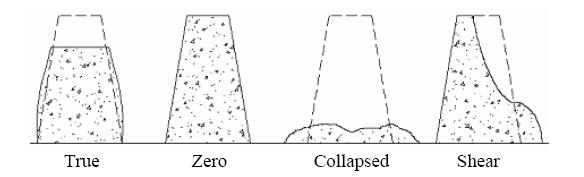

The slump is then interpreted by the following shapes:

- True Slump – the only slump that can be measured in the test. The measurement is taken between the top of the cone and the top of the concrete after the cones removal

- Zero Slump – Very dry mixes aim to have zero slump, and are used in road making.

- Collapsed Slump – This is an indication that the mix is too wet or that it is a high workability mix, for which a clump test is not appropriate

- Shear Slump – This result is incomplete, and should be retested