Category

- Concrete Technology

The construction of a concrete structure is an intensive process requiring vigilant cooperation between architect, engineer, contractor, and everyone else involved. From conception to execution there are a number of details that could be overlooked. If so, your structure is left at risked to early

As water is one of the most detrimental factors in deteriorating buildings the world over, the waterproofing system specified on a particular project is of the utmost importance. Further, one of the areas seemingly seen as an after-thought is the construction joints. Construction joints are placed in a concrete slab to define the extent of the individual placements, generally in conformity with a predetermined joint layout. Joints are essential to the construction process, but can also spell a disastrous amount of repair work.

Unfortunately, if these joints are not accounted for, water infiltration and structural weakness can and, more times than not, will occur. Without a waterproofing measure within the joints, water can pass through and infiltrate the concrete matrix. This will then leave the structure at risk to deterioration. Thus, a concrete waterproofing measure must also be taken to protect concrete joints – enter the waterstop.

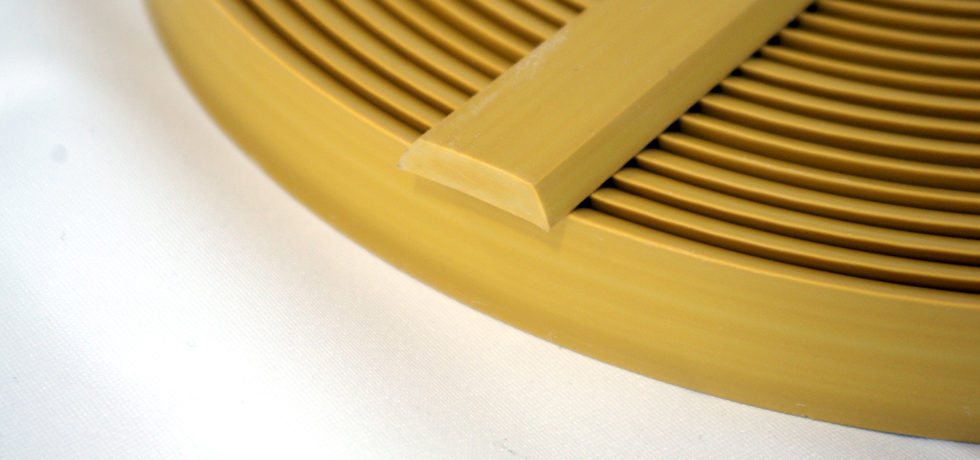

A waterstop is meant to be placed in the joint and when water comes in contact with them they expand and blocks the flow, thereby protecting the

Krytonite Swelling Waterstop is the new standard for joint protection in concrete. Not only does it protect joints against the flow of water, but can do so in projects with extreme hydrostatic water pressure. This protection occurs through its unique synthetic rubber technology that swells up to 4 times more than ordinary rubber or bentonite swelling waterstops. Krytonite produces enough swelling pressure to withstand extreme hydrostatic pressure, even when exposed to salt water or when used in chloride or sulfate contaminated soils.

The fact is, waterstops are used on projects throughout the world with varying degrees of success. Some deteriorate over time, others swell uncontrollably, and many are too tricky to install that they are doomed to fail from the beginning. Krytonite continues to prove it is the one waterstop that will continually block the flow of water and protect your concrete structure.