Category

- Concrete Design

- Concrete Waterproofing

Concrete is a fantastic building material when it comes to stability and durability. It’s strong, versatile, inexpensive, and available just about everywhere. Globally, it’s widely used to build everything from sidewalks to transportation tunnels.

Despite the popularity of concrete, its durability depends on how well you protect it, especially against water. Water is the primary enemy of concrete during service life, even though it’s essential to concrete production, placement, and curing.

Few substances are absolutely waterproof. Everything is permeable to some degree. And under the right conditions, water molecules pass through many things that we might normally consider to be waterproof.

So, Let’s Look at Concrete Waterproofing First — What Does It Mean?

In the construction industry, waterproof and watertight mean the same thing. So when we say something is waterproof, we mean that liquid water will not pass through in any measurable amount under commonly found conditions. Waterproofing concrete from water is typically accomplished by applying a barrier or external membrane of some kind to the surface.

It May Mean Involving External Membranes

External membranes, often used for waterproofing low-risk structural projects, are designed to stop water. But installation issues, punctures, and defects can lead to leaks. They also deteriorate over time, requiring costly repairs and replacement.

These Can Complicate Repairs

An external membrane waterproofing system applied to the surface of the concrete is typically on the outer foundation wall from where a leak is observed. So repairs can get complicated. This is because surface-applied systems are nearly always applied to the side of the structure that is buried below ground. As a result, it can’t be easily accessed. For example, a below-ground parking structure will have the membrane system on the outside of the perimeter wall. Any failure of the membrane will be impossible to repair because it is inaccessible.

Worse still, attempts to repair leaks from the inside can be problematic because it’s hard to tell where the water is actually coming from. A leak observed on the inside of the parking garage will likely be coming through a crack, hole, or joint.

However, that doesn’t mean that the membrane has failed directly on the other side of the wall at that point. Water can enter through an opening in the membrane then travel along a path of least resistance before finding a crack or other weak spot in the concrete to pass through. Common areas that allow water to pass are around corners, protrusions, pipes, laps, seams, and edges that have not been perfectly sealed.

Once water has infiltrated, it can flow freely, compromising the structure.

But That Doesn’t Mean External Membranes Don’t Have Their Uses

However, surface-applied products when installed correctly, have proven to provide effective waterproofing performance under a wide range of conditions. Drawbacks are generally cost, time, workmanship, vulnerability to damage, and difficulty to repair. As a result, methods to protect concrete from water without surface-applied barriers have been evolving for several decades.

It Can Also Involve Water-Repelling Chemical Admixtures

Water-repelling admixtures are sometimes referred to as hydrophobic. These products work by changing the surface tension so that water beads in contact with the concrete instead of absorbing in and through the pores. Many water-repelling admixtures incorporate some pore-blocking properties as well.

Such products can be very effective at keeping water out of concrete both above and below ground. However, they don’t work at resisting water that is under hydrostatic pressure. Once water pressure exceeds the surface tension within the pores of the concrete, the water is able to push past and through the concrete.

Water under pressure will do amazing things. High hydrostatic pressure, a common condition found in below grade foundations, tunnels, water containment tanks, and underground parking structures, requires an effective waterproofing system to be able to withstand water under pressure.

What Happens When Waterproofing Fails?

The common solution is to attempt repairs by injecting one of many available injection products into the concrete. Unfortunately, this often results in the water simply finding the next weakest spot to come through. Then, in turn, the repair crew finds themselves chasing leaks, which can be a costly exercise.

Ironically, the solution ends up being to use the concrete itself to block the water. So why not use the concrete itself as the waterproofing membrane?

It’s Time for Crystalline Technology

Gaining popularity around the globe over the last three decades is the integral crystalline waterproofing system. This system involves the use of integral crystalline waterproofing admixtures. And these admixtures are added to the concrete during mixing. In turn, they become part of the hardened concrete.

They make the concrete waterproof by blocking the passage of water through its capillary pores, cracks, and joints, by using the whole concrete mass as the waterproof membrane. Thus, it can replace the need for external waterproofing membranes.

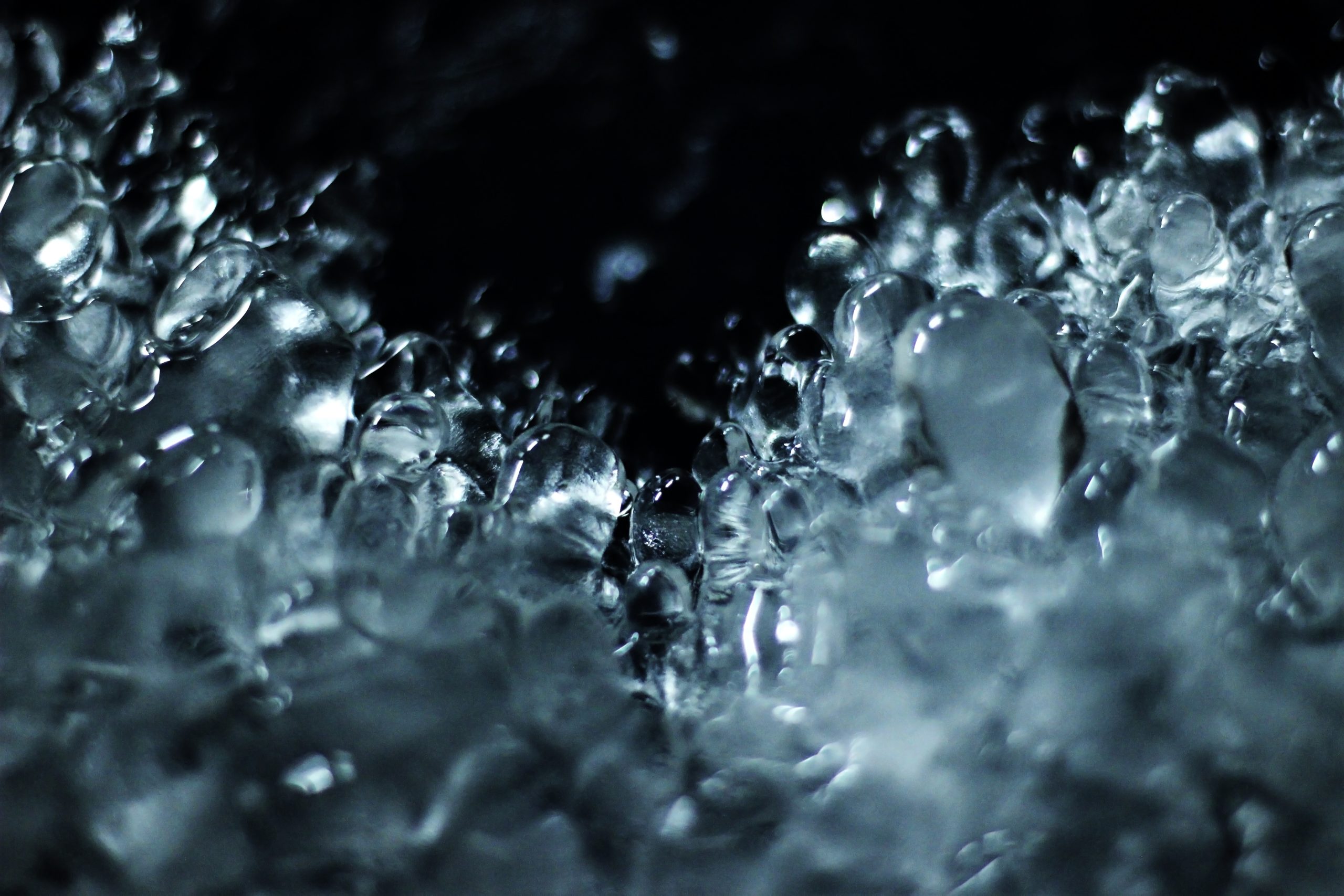

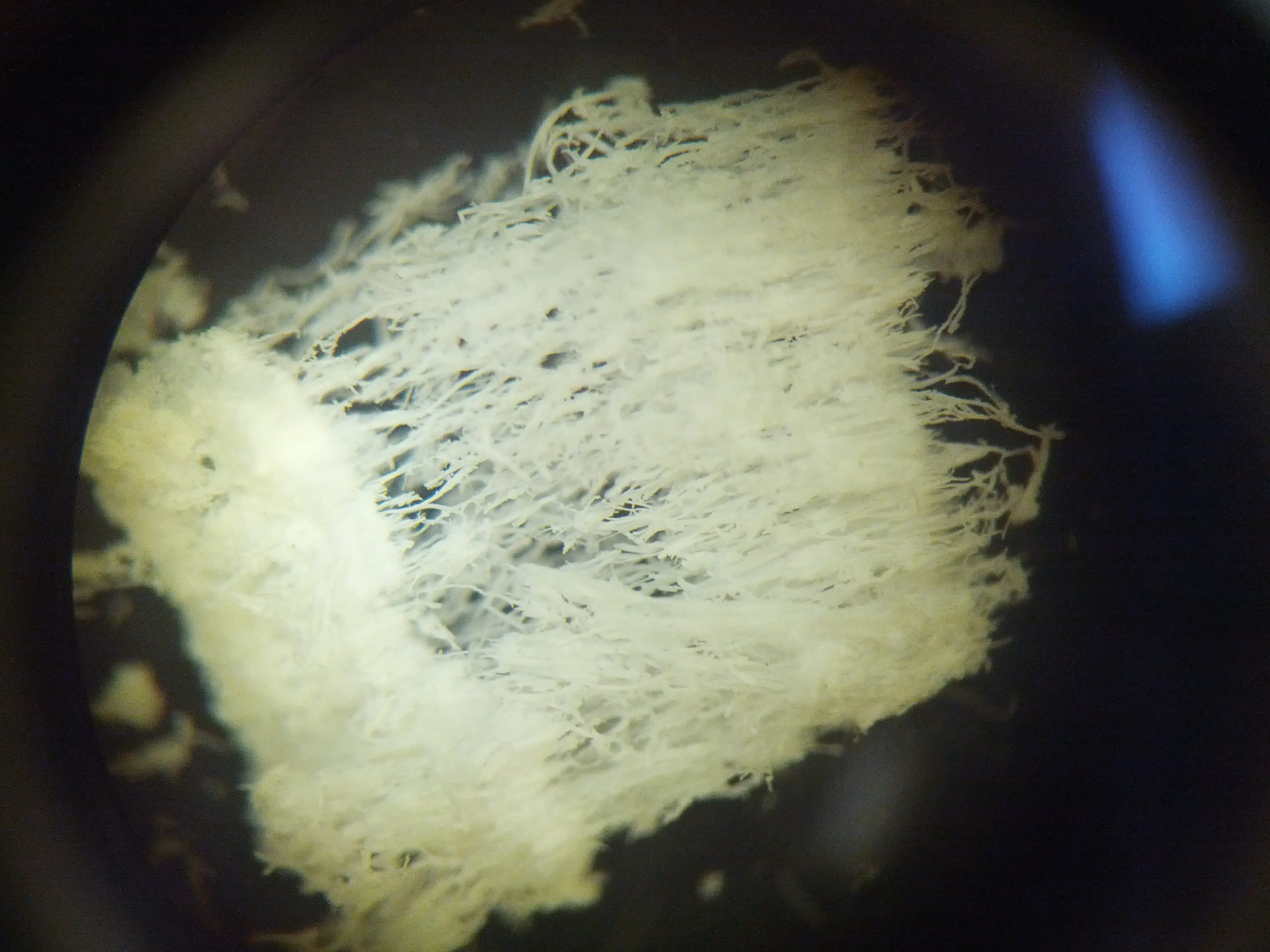

When added or applied to concrete, this crystalline technology chemically reacts with water and unhydrated cement particles. It does so by forming insoluble needle-shaped crystals that fill capillary pores and micro-cracks in the concrete and block pathways for water and waterborne contaminants. Any moisture introduced over the life span of the concrete will initiate crystallization, ensuring permanent waterproofing protection.

This technology is also known as Smart Concrete® because of its unique feature to lie dormant indefinitely within the concrete and react to any incoming water ingress. So if a new crack should form in the concrete and water begins to penetrate, the chemicals will react to form new crystals at the leaking location and grow to shut off the flow of water.

This feature is incredibly valuable because it means that the concrete has the ability to repair itself. So it is many times more reliable than surface-applied systems over the long run. It’s almost as if the structure is alive and can heal from a wound.

Just Keep in Mind It Only Self-Seals the Concrete

However, it is important to note that the repair is not structural. The concrete does not regain its pre-cracked strength as a result of the crystal growth. The use of the term self-healing is, therefore, a bit misleading. A better term for the process is self-sealing since this is what is actually happening.

Integral crystalline waterproofing products have proven effective for structures withstanding hydrostatic pressure. And in critical applications, a crystalline waterproofing admixture will provide the necessary performance. Its self-sealing ability will provide the most reliable long-term waterproofing solution available.

It Also Doesn’t Tolerate Concrete Moving

A drawback is that integral crystalline waterproofing products are not tolerant of constant movement. Even though a crystalline waterproofing admixture can self-seal cracks as they form, the process is slow. And constant movement will prevent a permanent seal from forming. For this reason, integral crystalline waterproofing products are best suited to rigid concrete structures, such as below ground parking, foundations, tunnels, and reservoirs. Then again, a well-designed structure with adequate reinforcement and proper jointing will allow a good integral crystalline waterproofing system to perform well in most cases.

Waterproofing Membranes Are No Longer Needed in Most Cases

Experienced designers and builders know that for most concrete waterproofing applications, surface-applied membranes are no longer the best concrete waterproofing technology available. Even newer, more advanced membrane systems are just improvements on obsolete technology.

The 30 years young and much more effective way to build waterproof concrete structures is integral crystalline waterproofing. After all, it turns the concrete itself into the membrane. As a result, this type of waterproofing cannot be punctured or damaged. And it will never wear out.

Are You Ready to Go with the Latest Concrete Waterproofing Option?

To effectively seal pores, cracks, and joints, you need reactive products like crystalline waterproofing admixtures, which are now being considered and selected more and more often. As a result, more and more high-risk projects are benefitting from them, making use of concrete with enhanced durability and longevity .

Advancements in this technology have led to the availability of more comprehensive crystalline waterproofing products (i.e., systems containing solutions for joints, penetrations, control joints, etc.), making it a highly versatile and sophisticated method for waterproofing. It speeds up construction in a number of ways by:

- Reducing steps in the building process

- Shortening construction schedules

- Minimizing the risk of labor and workmanship issues

- Providing greater design flexibility, allowing projects to be built right to the property line

- Ensuring a longer life span

- Lowering maintenance costs over the structure’s service life

To learn more, take a look at our section on Krystol® technology, where Kryton uses crystalline technology to its fullest.