Concrete’s compressive strength determines whether the concrete placed in a structure can carry the weight of what’s on top of it. Decisions such as when to strip forms, when to post-tension, when to remove shores, and when to terminate cold-weather protection are based on reaching a minimum level of concrete strength. Waiting too long to perform these operations is expensive; acting prematurely may cause the structure to crack or collapse.

Traditional concrete strength estimation using test specimens are often inaccurate resulting in poor resource planning and causing safety issues. Lack of real-time insight into concrete maturity status, time-consuming data acquisition and processing is a challenge.

A more efficient method of determining concrete maturity in real-time would help contractors, engineers and quality control professionals reduce construction schedules, save money and improve the quality of the structure. Unfortunately, it has been difficult to achieve – until now.

Maturix Addresses Concrete Monitoring Challenges

Maturix was developed by Sensohive Technologies, an emerging European technology company pioneering state-of-the-art sensors initially used by companies in the food and hospitality industry for monitoring coolers and freezers. Maturix was adopted by the construction industry to measure temperature and maturity of in-situ and precast concrete.

Maturix for construction uses thermocouple cable embedded in concrete during casting and connected to a reusable wireless transmitter to relay critical information on the curing process in real-time allowing a construction manager to monitor and plan their schedules with certainty.

Sensohive’s wireless sensors are widely used in European construction projects including major projects built by Paschal GmbH, VolkerWessels, and Kruse Smith, among others.

How Do Maturix Sensors Work?

Maturix wireless technology is incredibly user-friendly and made for fast, easy and risk-free application at jobsites.

A concrete sensor cable is mounted to the reinforcement before the wet concrete is used. The sensor cable is connected to a sensor device and the monitoring is started on the cloud-based software accessible through any web browser or on the smart phone.

The use is then able to follow the strength and maturity of the concrete in real-time. Notifications can be sent by SMS or reviewed on a customized dashboard. All data is stored and saved in reports ready to share.

They Offer Accurate Temperature and Maturity Measurement in Real Time

The ability to accurately estimate the in-situ strength of concrete with sensors produces consistent and predictable results to verify that specified requirements are safely met maximizing efficiency and ensuring concrete quality.

Reliable, up-to-the-minute information on concrete strength and temperature allows contractors to make more timely decisions enabling them to complete contracts on or ahead of schedule.

Expediting faster construction programs through real-time concrete monitoring reduces costs allowing assets to be used sooner thereby maximizing profits.

That Includes Remote Data Collection

Conventional single-use concrete sensors on the market today collect data through Bluetooth NFC transmitted to a phone or device have a short broadcast range. This requires a person to physically visit the job site to collect data, which is labour intensive and time-consuming.

Maturix wireless sensors enable contractors to optimize critical construction operations by monitoring concrete maturity from their own connected device, being notified when strength targets (or critical thresholds) have been met, and knowing exactly when it’s time to come back to remove formwork and apply load on a structure.

These Reusable Sensors Even Come with Batteries That Last for Up to 10 Years

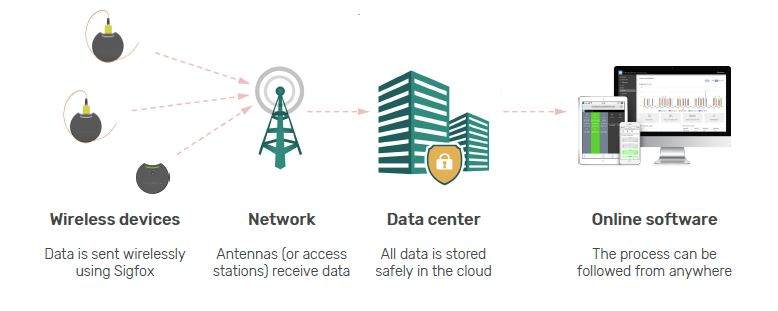

Real-time monitoring of structures is an evolving field in the construction industry made possible through the rapidly expanding Internet of Things (IoT) – the interconnected digital network allowing everyday objects to be embedded with electronics collecting and sharing data. Maturix™ technology runs on the Sigfox 0G network, the world’s largest IoT network covering 1 billion people in 65 countries. Sigfox’s long-range and low-power demand network allows Maturix’s sensor batteries to last for up to 10 years. No other concrete sensor can claim such a long life, reliability, reusability and be completely wireless.

Maturix makes concrete monitoring temperature and strength development easy and affordable. We are already seeing more and more contractors using the technology to increase construction efficiency and productivity.

In September 2019, Kryton added Maturix wireless technology to its Smart Concrete® product offering through a partial acquisition of Sensohive Technologies. Kryton will be an exclusive distributor of Maturix in North America. Contact us to learn more about the technology at sensors@kryton.com or +1.604.324.8280.