Category

- Concrete Best Practices

There are over 75,000 drinking water systems in the United States, including over 2 million miles of underground pipes and thousands of water containment tanks. These systems are responsible for delivering safe, reliable water to hundreds of millions of people across the nation.

Unfortunately, many of these systems are aging and underfunded.

A water main breaks every two minutes, and an estimated 6 billion gallons of treated water are lost each day. Above and below ground, water containment tanks are leaking, which either allows contaminants to enter the supply or causes valuable water to be wasted.

This article explores the current trends and challenges facing water containment, examines traditional solutions and their limitations, and discusses the role of new waterproofing innovations, particularly crystalline technology, in addressing these issues.

The Water Containment Landscape

The water containment industry is experiencing significant changes driven by increased regulatory scrutiny, rising maintenance costs, and the push for more sustainable solutions to water management.

According to the American Water Works Association (AWWA), there is a growing emphasis on proactive maintenance and the adoption of advanced technologies to extend the lifespan of water storage infrastructure. In addition, municipalities are prioritizing infrastructure upgrades to meet stricter environmental standards and ensure the reliability of water supply systems.

Addressing Aging Infrastructure

One of the most pressing challenges is the aging infrastructure of water containment tanks. Many tanks across the country are nearing or exceeding their expected service life, leading to increased risks of leaks, contamination, and structural failures. The EPA’s most recent Drinking Water Infrastructure Needs Survey highlights the urgent need for investment in the rehabilitation and replacement of these aging systems.

Environmental and Health Concerns

Leaks and contamination in water containment tanks pose significant environmental and health risks. An opening as small as a few millimeters could prove the difference between drinking a glass of clean water and one contaminated by chemicals, insects, or animal feces that can cause diarrhea, respiratory infections, or worse.

Experts estimate that contaminated drinking water causes tens of millions of illnesses each year, contributing to as many as 1,000 American deaths.

Reports from the EPA and other regulatory bodies underline the necessity for stringent tank monitoring and maintenance practices to protect public health.

Maintenance and Repair

Routine maintenance and repair of water containment tanks are critical to preventing contamination and ensuring structural integrity.

However, maintenance practices are often reactive rather than proactive, leading to costly emergency repairs and service disruptions. The State of Infrastructure Report emphasizes the importance of adopting a preventive maintenance approach to mitigate these risks.

Traditional Solutions for Waterproofing Water Containment Structures

Traditional solutions for water containment tank maintenance include the application of external coatings, liners, and membranes to prevent leaks and contamination. While these methods can be effective in the short term, they often come with limitations:

1. Short Lifespan

Coatings and liners can degrade over time due to environmental exposure, requiring frequent reapplication and maintenance.

2. Application Challenges

Proper application of these materials can be labor-intensive and subject to human error, which can compromise their effectiveness.

3. Limited Durability

Traditional methods may not withstand the harsh conditions within water containment tanks, such as fluctuating temperatures and chemical exposure.

Crystalline Technology for Waterproofing

Technological advancements have introduced more durable and effective solutions for water containment tanks. One such innovation is crystalline technology, invented by Kryton over 50 years ago, which offers several advantages over traditional methods.

How Crystalline Technology Works

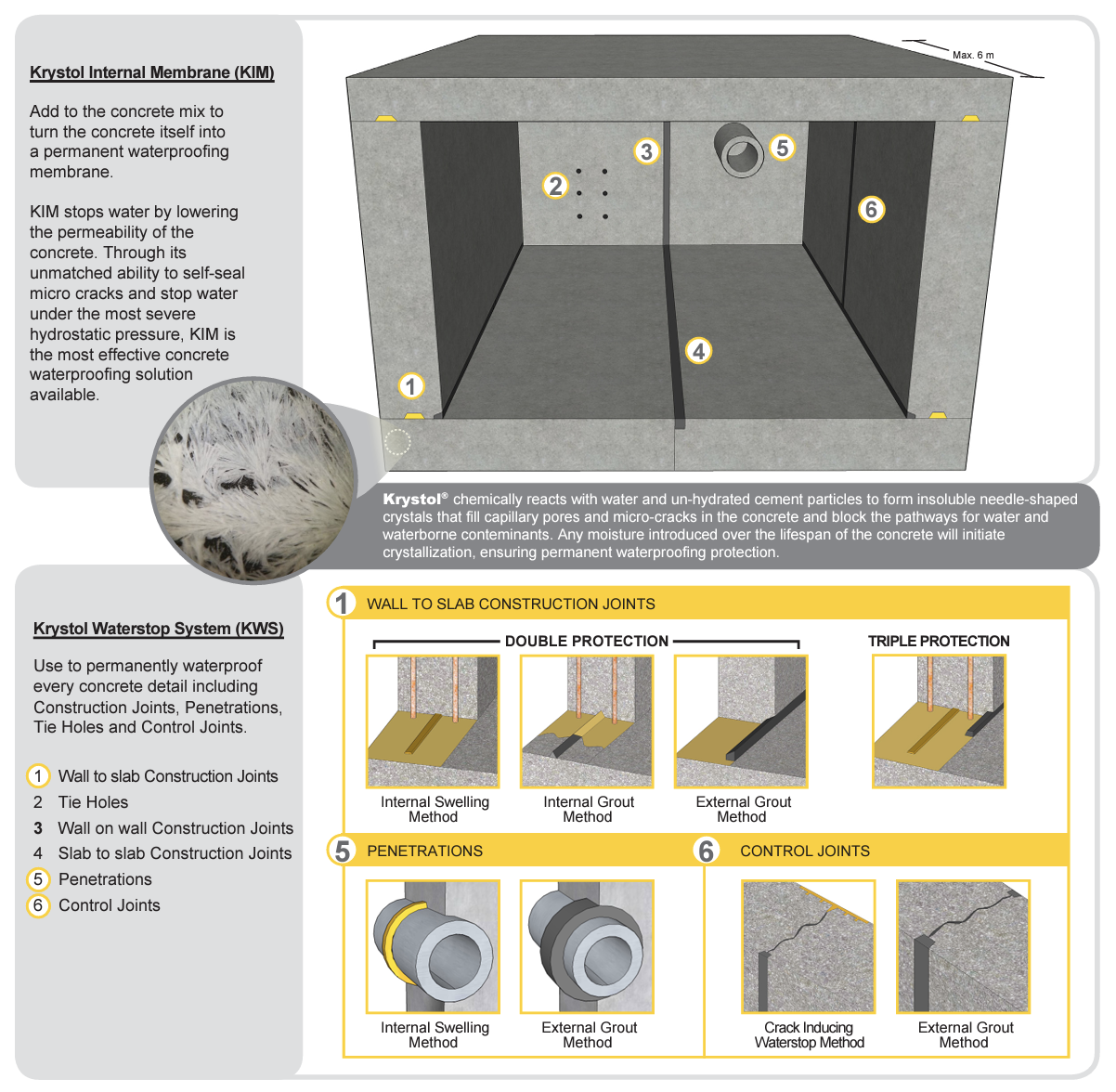

Kryton’s technology, Krystol Internal Membrane, involves adding a crystalline admixture to the concrete mix used in tank construction or repairs. This admixture chemically reacts with water and cement to form insoluble needle-shaped crystals within the concrete matrix. These crystals fill capillary pores and micro-cracks, blocking pathways for water and contaminants and ensuring permanent waterproofing protection.

Unlike traditional coatings and liners, crystalline technology integrates into the concrete, providing long-term protection without the need for reapplication. The technology allows for the self-sealing of new cracks that may form over the tank’s lifespan, ensuring ongoing protection. Crystalline technology offers superior resistance to harsh environmental conditions, including chemical exposure and freeze-thaw cycles.

Experts emphasize the importance of adopting advanced technologies to address the challenges of aging water containment infrastructure. According to the AWWA integrating innovative solutions like crystalline technology can significantly enhance the durability and reliability of water storage systems.

Constructing Watertight Structures

Municipalities can take the risk out of creating watertight tanks from the beginning by using Kryton’s Krystol Internal Membrane (KIM) admixture and Krystol Waterstop Joint System. With Kryton, waterproofing is built right into the concrete, eliminating the need for membranes. Kryton’s Krystol technology provides excellent resistance to harmful caustic effects of contact with sewage, wastewater and waterborne chemicals such as sulfates, chlorides, and acids. Transform walls and slabs into impenetrable barriers using KIM or Krystol Broadcast and create watertight construction joints and pipe penetrations using the Krystol Waterstop System.

Real-World Examples of Crystalline Technology in Action in Water Containment

Case studies from various municipalities demonstrate the practical benefits of cystalline technology in extending the service life of water containment tanks.

Seguin Water Tank, Texas

The city’s 7 million-gallon water tank was found to be leaking in 2012, and the repair team chose to use Kryton repair solutions because Kryton’s products saved them time, have a track record of consistent performance, and promise permanent waterproofing protection. Read More

City of Langley, BC

In 1976, the City of Langley applied Kryton’s Krystol solutions to one of its water containment tanks. While other tanks required repairs by 1981, the Krystol-treated tank remained watertight and functional. As of 2000, it continued to perform as specified, showcasing the long-term efficacy of crystalline technology. Read More

TreePeople Center Underground Cistern

The TreePeople Center in Los Angeles, California, features a 950,000-liter (250,000-gallon) underground concrete cistern that captures rainwater to irrigate the center’s gardens and forests. Because conventional waterproofing membranes deteriorate over time, the center’s owners opted to use Krystol Internal Membrane (KIM) and the Krystol Waterstop System, which provide permanent protection against leakage and eliminate costly repairs and maintenance. Read More

Conclusion

While aging infrastructure and maintenance issues pose significant risks to water supply across the United States, technological advancements like Kryton’s crystalline technology offer promising solutions.

By adopting these innovative approaches, municipalities can enhance the durability and reliability of their water storage systems, ensuring a safe and sustainable water supply for the future.

For product inquiries, technical assistance, or to locate a Kryton distributor in your area, fill out our contact form, and someone will get back to you shortly.