Built to Last: Why Data Centers Need Durable Concrete More Than Ever

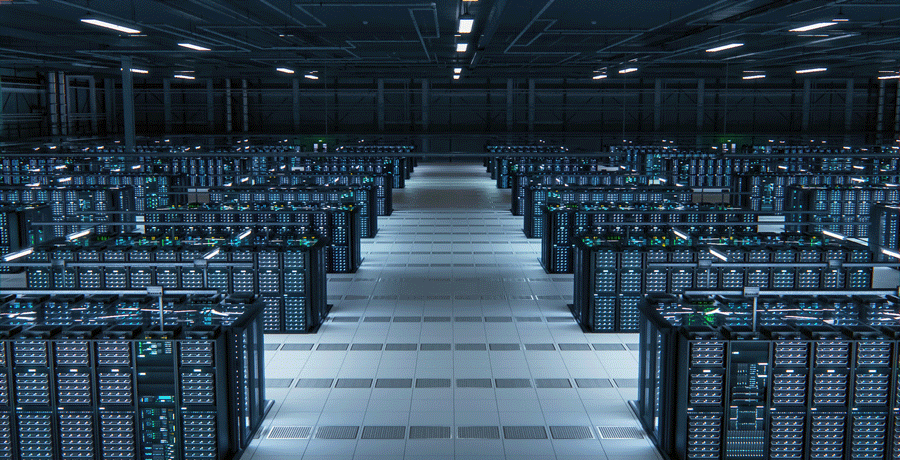

As the global demand for high-performance data centers continues to surge—driven by cloud computing, AI, and automation—many operators are rethinking how they approach the design and resilience of their facilities. And one element is finally getting the attention it deserves: the durability of concrete.

While concrete might seem like a passive component of a data center, it plays an active, load-bearing, and high-traffic role in maintaining operational uptime. From supporting thousands of square feet of racks and servers to withstanding constant movement from robotic handlers, today’s concrete infrastructure is under increasing pressure—both literally and figuratively.

The Cost of Overlooking Concrete Performance

According to Forbes, the average cost of a data center outage now exceeds $9,000 per minute, with major incidents climbing to over $1 million per hour. Often, these failures start with something as minor as a hairline crack or slow-developing abrasion. Water seepage, even when not visibly penetrating the slab, can corrode internal steel reinforcement, compromise insulation systems, and ultimately require costly shutdowns and structural repairs.

And it’s not just water from the outside. Many data centers use millions of gallons of water daily to manage internal cooling systems. That water, circulating through pipes, trays, and conduits integrated with or running over concrete elements, increases the chance of long-term deterioration—especially when standard concrete is used.

More Robots, More Abrasion

As automation becomes the norm, the mechanical movement of robotics introduces a new challenge: abrasion. Repetitive wheeled traffic, pallet handling systems, and autonomous guided vehicles can quickly wear down untreated concrete floors, leading to uneven surfaces, increased maintenance, and safety hazards for both people and machines.

Hard-Cem®: Concrete That Fights Back

This is where Hard-Cem®, Kryton’s integral concrete hardener, delivers real value. Unlike dry-shake hardeners or surface treatments, Hard-Cem is added directly into the concrete mix, increasing the abrasion and erosion resistance of the entire slab—not just the surface. It strengthens the concrete throughout its depth, making it ideal for:

- Robotic warehouse and server room floors

- High-traffic aisles and staging areas

- Concrete surfaces exposed to cooling water, condensate, or heavy equipment

Hard-Cem has been proven to double the wear life of concrete, protecting mission-critical environments against surface degradation, joint curling, and the hidden costs of floor repairs and resurfacing.

Waterproofing That Works From Within

For below-grade walls, foundations, and other water-exposed areas, Kryton’s Krystol Internal Membrane™ (KIM®) offers an integral waterproofing solution. Like Hard-Cem, KIM is added directly to the concrete at the batching stage, turning it into a self-sealing, water-resistant barrier that reacts to moisture and blocks it from moving through the concrete over time.

Together, KIM and Hard-Cem form a comprehensive durability system that makes concrete not just stronger—but smarter.

Why This Matters Now

Data centers are expanding rapidly—often into regions with high water tables, seismic risk, or extreme seasonal temperatures. The concrete used in these environments must withstand more than basic loading. It must perform under pressure, resist moisture and erosion, and stand up to the evolving demands of automation.

Benefits of Kryton’s Concrete Durability System

- Abrasion Resistance: Floors resist wear from robots, carts, forklifts, and maintenance equipment.

- Waterproof Performance: No reliance on membranes or coatings; KIM keeps water out for the structure’s lifespan.

- Long-Term ROI: Fewer repairs, less downtime, and stronger protection for sensitive infrastructure.

The Bottom Line

Concrete is no longer just a static structural element—it’s a performance-critical asset in your facility. Specifying advanced admixtures like Hard-Cem and KIM is a proactive step toward avoiding costly failures, reducing long-term risk, and ensuring operational uptime in the data centers of today and tomorrow.

Learn more about Kryton’s durability solutions for data centers and mission-critical infrastructure contact us.