Last time in this interview series, we looked at just how effective Hard-Cem® is as a solution for increasing concrete abrasion resistance. (For a recap, take a look at our first part and second part in this interview series!)

Unlike conventional surface-applied products, Hard-Cem has a worry-free application process. And on top of that, it has been proven to be effective through third-party testing. Part of that testing involved a modified ASTM C627 test, which showed just how resistant Hard-Cem made concrete to abrasive forces.

However, that’s not all it has going for it. Hard-Cem can also help construction professionals with their sustainability efforts. To see how, we asked Kryton Technical Director Jeff Bowman for more insight.

First, why don’t we review the environmental concerns surrounding concrete?

I’m sure many people are aware that roughly, for every 1 ton of Portland cement that’s manufactured, 1 ton of CO2 is released into the atmosphere. But of course, we don’t make buildings out of cement. We make them out of concrete. So I think it’s more useful to look at the final carbon load of the concrete itself.

Where can we learn about the final carbon load of concrete?

Now, there are many industry resources for this. The one that I’d like to draw from today is the Canadian Ready-Mixed Concrete Association’s environmental product declaration. It has a wide range of information and breaks concrete down by strength class. It also publishes industry benchmarks for each strength class.

But for just a broad view of the information displayed, you can see that depending on the concrete strength and many other factors, the carbon load of that concrete is normally going to range about 250 kg to 500 kg of CO2 per cubic meter of concrete.

That’s a significant environmental investment. So you really want to make sure your concrete is going to be durable and last a long time with minimal maintenance.

How does Hard-Cem help mitigate this carbon issue?

Well, first of all, just by having Hard-Cem reduce the wear and tear of abrasion on a concrete slab, you’re reducing, delaying, and often preventing some of that maintenance activity you’d otherwise need to do to replace that concrete or grind it down and resurface it. You can avoid using more concrete to fix it at a later time.

But to ensure good abrasion resistance, a higher strength concrete is used instead. This increases the carbon footprint and is an inefficient use of resources. Hard-Cem may allow the lower strength option to be used instead while still designing for abrasion resistance. This can allow the use of more environmentally efficient concrete without sacrificing abrasion performance.

So, Hard-Cem can help reduce the carbon footprint now and down the road?

Yes, it can.

Remember, depending on the application, oftentimes, a higher strength concrete may introduce some problems that are actually detrimental to the overall performance of the job, such as increased shrinkage, cracking, and curling.

So using a more conventional mix with Hard-Cem can help you avoid these problems while still achieving excellent abrasion durability.

What about Hard-Cem’s carbon footprint?

The carbon footprint of Hard-Cem is very small. It’s only a percentage or two of the overall mix. As we often see with admixtures, it gives you very good performance value relative to its environmental impact.

What does all that mean for the lifetime carbon footprint of a structure?

Being able to produce a sustainable mix now is a very worthy goal. But it’s true that it’s also important to take a look at the lifetime carbon footprint of that structure. Depending on the maintenance and replacement cycle, the lifetime carbon footprint can be much higher than the original construction cost.

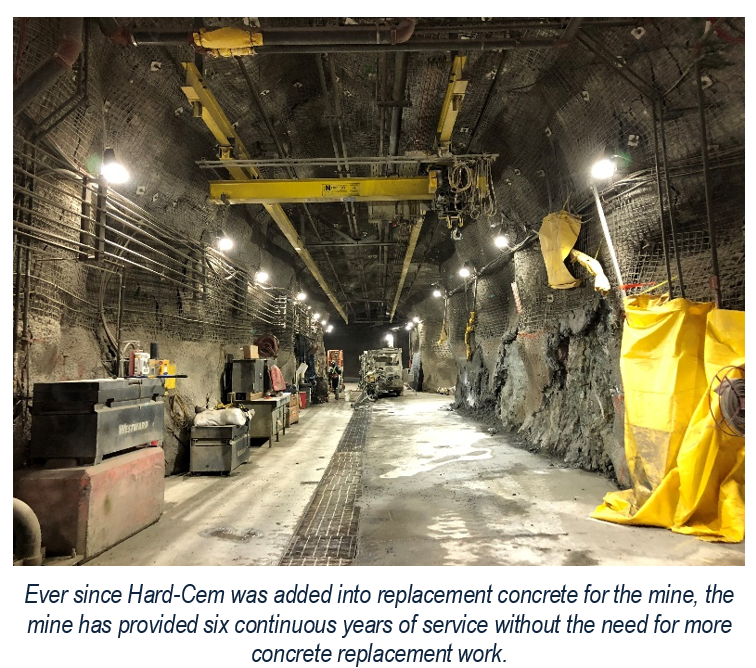

Now, we have a really interesting case study on this: the New Afton Mine. This is near Kamloops, British Columbia, Canada, and was built in 2011.

In the ore collection and processing area, within three years, the mine had so much wear and tear just from the mining equipment. And with the ore on the ground being pressed into the concrete and ground between those wheels, the owners had to replace, not just resurface but replace, the concrete in that area within only three years. So they were set on a three-year replacement interval, which is not very sustainable.

But in 2014, they replaced it with Hard-Cem concrete, and that concrete is still performing today. So what you can see here is that by investing in durability, they’ve been able to skip at least two replacement events. And they’re actually partway through what would have been their third.

In short, Hard-Cem has reduced the lifetime carbon footprint by almost 50%. And that’s just so far.