The industrial market is experiencing a significant boom, with warehouses, distribution centers, manufacturing facilities, and transportation sectors expanding rapidly across North America.

This growth is largely driven by the resurgence of manufacturing in the US, most notably evident in the automotive industry’s pivot toward electric vehicles (EVs) and battery manufacturing. Global OEMs in other manufacturing sectors have also committed to opening new production facilities in US locations to solve persistent supply chain issues by boosting local production capacity for parts and materials.

These manufacturing facilities require robust protection for their concrete floors to withstand the heavy-duty operations carried out on a daily basis. Unlike in the past, where options were limited, today’s concrete industry offers a range of hardening and durability enhancement technologies for concrete floors.

In this blog post, we’ll explore the pros and cons of some of these solutions and share a real-life case study from a manufacturing facility in Massachusetts that successfully replaced its production floor with a more durable, abrasion and erosion-resistant slab that meets its traffic and health and safety needs — while requiring less maintenance and downtime.

Durability Requirements of Industrial Floor Slabs

Industrial floors are subject to extreme conditions, including heavy loads, constant traffic, and exposure to abrasive and corrosive substances. The hardening and protection of concrete floors are critical to ensure they can withstand these conditions without significant wear or damage.

Curling, and shrinkage are problematic in industrial floors due to the sheer quantity of joints required in a large floor space. If the joints curl up, machinery will hit them, creating a maintenance nightmare — not just related to the floor slab but also to the machinery.

As industries progress toward smart factory transformations, durable and abrasion-resistant floors are a must-have for optimal machine operation and operator health and safety.

Concrete Durability in Resisting Damage

The primary goal of concrete durability is to resist abrasion, wear, and damage, and extend the floor’s overall service life. By specifying and selecting appropriate abrasion and erosion-resistant concrete solutions, architects, engineers, and contractors can enhance the resistance of their clients’ concrete to physical and chemical stresses, and improve its impermeability — and its ability to withstand harsh environments.

Ultimately the right durability solutions will ensure a floor slab is equipped to handle the demands of industrial operations, resulting in reduced maintenance costs and an extended service life.

Pros & Cons of Common Concrete Hardening Solutions

Traditional abrasion and erosion solutions like dry shakes or liquid densifiers carry inherent challenges that make them ineffective in the long term.

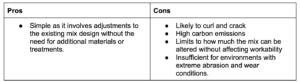

1. Cement Alterations

Altering the concrete mix by increasing the cementitious content and reducing the water-cement ratio can inherently make the concrete harder and more durable. While this might appear as the simplest solution for abrasion and erosion resistance, increasing cement content presents its own problems.

Firstly, concrete that is too strong often results in curling and cracking, undermining the very durability it aims to enhance. In addition, cement production is notoriously carbon-intensive. Ramping up its usage exacerbates environmental challenges and results in a greater carbon footprint.

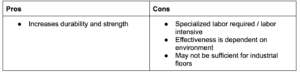

2. Special Curing Techniques

Proper curing will increase durability, strength, water-tightness, abrasion resistance, volume stability, and resistance to freezing and thawing. Techniques such as wet curing or the application of curing compounds help retain moisture in the concrete, ensuring optimal hydration and strength development.

However, specialized curing requires careful monitoring and control to ensure consistent application and effectiveness across the entire concrete surface. Some curing methods may be labor-intensive or require specific environmental conditions to be effective.

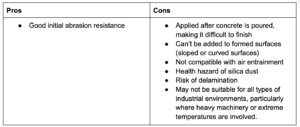

3. Dry Shakes

Dry shakes provide a protective layer on the concrete surface, defending against chemical spills, abrasion, and impact. However, they are limited as they are incompatible with air entrainment and many SCMs and cannot be used on formed surfaces.

On flat surfaces, dry shakes typically provide decent initial abrasion resistance if applied correctly. The complexity involved in their application, however, often leads to a negative impact on their overall performance. The primary challenges revolve around ensuring an even and consistent distribution of the material and effectively handling surface moisture both prior to and during the application. Dry shakes are applied after the concrete is poured and require additional expert labor and equipment for the application, which often creates schedule delays and incurs additional costs.

In addition, most dry shakes pose significant risks on site. The silica dust generated during application is a recognized health risk and has broader environmental implications. For this reason, workers applying the shake and workers in the vicinity of the application area are required by OSHA to adhere to multiple safety precautions.

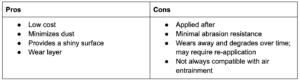

4. Liquid Densifiers/Hardeners

Applied to the concrete surface, densifiers react chemically to form a harder, more abrasion-resistant finish. They can be effective in increasing surface durability, particularly against surface wear and abrasion, but the benefits are primarily limited to the surface, offering little to no improvement to the concrete’s internal structure.

Despite being cost-effective and offering some superficial benefits, liquid densifiers (sometimes referred to as hardeners) possess several technical shortcomings. Like dry shakes, they are applied post-pour and require skilled laborers for application.

Liquid densifiers are well known to degrade over time. In the best case, they require frequent re-application, which isn’t just labor-intensive but also results in slab downtime and lost productivity. In the worst case, they result in the replacement of the entire slab due to abrasion and erosion that takes place once the wear layer delaminates.

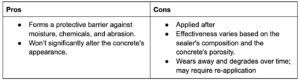

5. Penetrating Sealers

Penetrating sealers are similar to liquid densifiers and dry shakes. They react with compounds and minerals within the concrete to provide a protective barrier and improve the abrasion resistance of concrete.

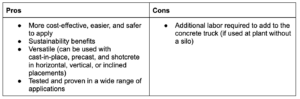

6. Abrasion and Erosion Resistant Admixtures

Admixtures that add durability integrally to concrete can deliver long-lasting, abrasion and erosion-resistant concrete while also lowering the embodied carbon emissions of an industrial floor project.

Kryton® Hard-Cem is one example of this. It is a concrete admixture for abrasion and erosion resistance that — unlike dry shakes and liquid densifiers — is integrated directly into the concrete mix to improve the durability, lifespan, and sustainability of concrete structures. It uses a unique metal-mineral microstructure that delivers high-performance, low-carbon concrete with no additional floor treatments required. Kryton Hard-Cem significantly reduces replacement and repair requirements and more than doubles the concrete’s wear life, effectively lowering the structure’s embodied carbon footprint over its lifetime.

Case Study: Old Neighborhood Foods Facility Upgrade

Old Neighborhood Foods, a manufacturer of processed meat products with 500 employees based in Lynn, Massachusetts, aimed to enhance the durability and longevity of its renovated facility’s industrial floor.

The design phase goals were focused on selecting a concrete solution that would provide a robust, long-lasting working slab capable of supporting heavy equipment and traffic, including forklifts, pallet jacks, and trolleys. The backdrop of this project involved new EPA mandates concerning food processing, particularly the transition to high-pressure processing (HPP) technology for meat sausage processing. This technology necessitated a highly stable and durable floor to accommodate the new equipment and the surrounding operational activities.

Selection and Application of Durability Solution

The choice to use an abrasion and erosion-resistant admixture was influenced by the need for a concrete floor that offered enhanced durability, reduced permeability, and superior resistance to abrasion and chemical exposure.

Kryton Hard-Cem, a high-performance admixture, was selected for its proven ability to integrate seamlessly into the concrete mix. Hard-Cem’s integral nature meant that even if the surface were to experience superficial damage, Hard-Cem’s protection would extend throughout the depth of the concrete, maintaining its structural integrity.

The facility’s new concrete floor exhibited exceptional durability and resistance to the harsh conditions typical of food processing operations. The enhanced abrasion and chemical resistance of the floor meant that Old Neighborhood Foods could anticipate significantly lower maintenance costs and extended service life for their facility.

Moreover, the use of Kryton Hard-Cem contributed to a more hygienic processing environment by reducing the floor’s permeability, making it less susceptible to water penetration and contamination. This aspect was particularly crucial given the stringent cleanliness standards required in food processing.

Building for the Future with Durable Concrete Solutions

As the industrial sector continues to expand, the demand for durable, abrasion and erosion-resistant concrete floors has never been higher.

Old Neighborhood Foods’ facility upgrade demonstrates the benefits of incorporating advanced admixtures like Kryton Hard-Cem into concrete mixes to extend the service life of industrial floors and reduce the need for frequent repairs and replacements.

For more information, contact our team.