Category

- Concrete Sensors

Nowadays, it’s more important than ever that contractors keep a close eye on their concrete’s development. After all, material delivery lead times are double or more than what they used to be before the pandemic. And the cost of materials is still relatively volatile. So if anything goes wrong during the development of the concrete and the material needs to be replaced, it could waste a significant amount of time and money. But contractors can avoid all that by ensuring the concrete develops effectively the first time around. There are many ways to accomplish that. Some of which often include relying on break tests. However, contractors might want to also consider calculating the maturity of their concrete.

They can do this with a variety of devices, but we recommend going with Maturix® Smart Concrete® Sensors. We’ve gone into brief detail before on how they can help boost worksite efficiency, but today, we’re going to give a more in-depth look at how exactly contractors benefit from calculating the maturity of concrete with Maturix.

The Most Evident Benefit Is the Ability to Optimize Construction

To start, let’s take another look at that efficiency benefit.

It’s all thanks to the Maturix setup and functionality.

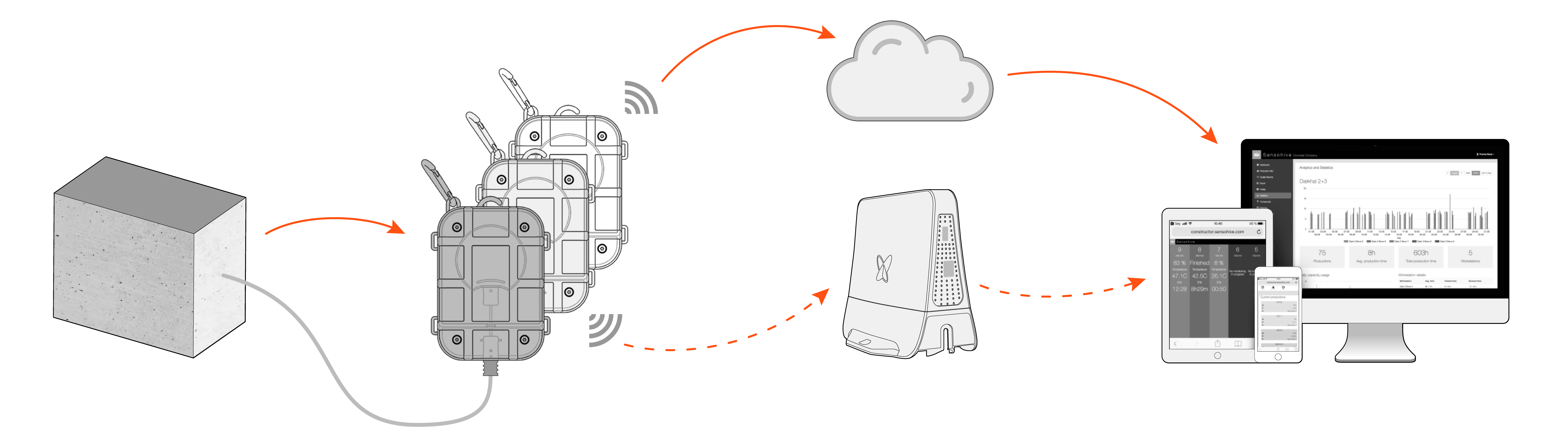

Contractors begin by embedding a type K thermocouple wire in concrete. Then, they connect the other end of it to a Maturix transmitter. Once connected, the transmitter automatically starts measuring the temperature of the concrete. It then sends that data to a cloud-based platform, which determines the compressive strength of the concrete. All of which gets displayed to Maturix users on any connected device they choose.

It’s an automated process that comes with plenty of efficiency benefits, including the following.

It Takes Out the Costly and Time-Consuming Guesswork for Determining the Maturity of Concrete

Traditionally, contractors are often concerned about maintaining the schedule and budget of a project. And it’s mainly due to how many uncertain variables they have to consider.

One of the causes of this uncertainty is simply due to conventional concrete development practices.

After All, Traditional Methods Are Not That Efficient

Under those practices, contractors are required to conduct break tests to determine the compressive strength of their concrete. However, it’s hard to tell when to start these tests.

Even after contractors follow through with them, the process of taking concrete samples and conducting break tests is highly time-consuming and costly. Contractors need to spend time gathering the samples and sending them off to a testing laboratory each time they want to see how far their concrete’s strength has developed. Then, they need to wait for those results to come back.

Once available, however, these results don’t give contractors a full picture, making it hard to determine when to remove formwork.

It’s a process that contractors have to repeat multiple times, making it a costly, inefficient time sink that takes up a lot of unnecessary use of equipment and personnel.

But Contractors Don’t Have to Rely on Them Alone

Luckily, Maturix can help improve the process. With its ability to instantly and continuously monitor the temperature and strength of concrete and send that monitoring data to a connected device, contractors know how well their concrete is developing at all times. As a result, they can easily determine when to remove formwork. That means they can rely on fewer break tests, which cuts down on the expenses and time spent on preparing, testing, and waiting on more concrete samples at a laboratory.

It also means that contractors can speed up their work. Formwork removal can be done earlier. And planning can be done more quickly and efficiently as they have all the data they need in one spot.

Calculating the Maturity of Concrete with Maturix Also Provides More Accurate Strength Estimations

With Maturix, contractors get more than just a continuous look at their concrete’s development whenever and wherever they want. They also get a more accurate look.

But why is that? Don’t break tests work just fine?

Typical Strength Estimations Come with Inherent Inaccuracies

It’s true that break tests can offer some insight. After all, strength estimations have been crucial to construction. They tell contractors when a concrete structure is or is not strong enough to withstand added weight. So break tests have been designed to give contractors at least some idea of how far along a concrete structure is capable of handling being under load.

But break tests aren’t looking at the actual concrete structure itself. Instead, they’re testing samples from that structure.

Due to the significant size difference between a structure and its samples, there is an inherent difference in their temperatures. But the difference doesn’t stop there. Because of their vastly different temperatures, their strength development also occurs at a different rate. So for instance, if the structure generates more heat than its sample solely due to its size, it will develop strength much faster than the low-heat concrete sample.

Determining the Maturity of Concrete Can Eliminate That Concern

Accurately determining the temperature and strength of concrete no matter the size is not something a contractor could calculate for with break tests. But they can with Maturix.

As Maturix calculates the maturity of concrete, it is able to use the temperature history of a structure and a concrete mix’s specific strength development information to accurately estimate the structure’s compressive strength.

It ensures that even if contractors are obligated to use break tests for a project, they can still get more accurate estimations just by calculating the maturity of concrete with Maturix.

There’s Also Less Hassle When It Comes to Documenting All That Data

Because Maturix logs and reports the temperature and strength data it collects from its concrete monitoring, contractors have an opportunity to make their documentation work that much easier than it typically would be.

Without Maturix, However, Data Collection Is Often Time-Consuming and Undesirable

Normally, contractors would have to send someone to the worksite to manually collect concrete monitoring data from temperature data loggers, short-range sensors, or concrete samples. All of which takes an enormous amount of time. On top of that, this form of data collection can be prone to human error as a worker often has to input that data into computer software.

That’s only a small amount of the required documentation too. A construction project requires many other documents. Some of which involve validating a project’s quality, which can be hard to obtain as many workers consider filling out that documentation as secondary compared to work they consider more practical.

But with Maturix and Its Automated Systems, Data Collection Is a Breeze

It doesn’t take long to realize how Maturix’s automatic logging and reporting of concrete temperature and strength data can help with documentation. It eliminates the need to manually collect that data. And it’s even able to display that data in a way that gives viewers the entire temperature history and correlating strength development of a concrete structure.

It can even allow contractors to export the data in multiple formats. So they can share it with clients and other important parties.

It’s a great way to prove concrete quality and development that doesn’t use up valuable worker time.

Lesser Known Is Maturix’s Ability to Increase Safety and Reduce Defects

All that efficiency doesn’t just make for clearer decision-making, more accurate results, and easier data collection. It also leads to making concrete and the surrounding worksite much safer.

It’s a less obvious benefit, but it becomes much more evident when Maturix is put to the test. As soon as contractors have that constant accurate concrete monitoring, they can see the internal temperature and the differential temperatures changing in real time. So it becomes easier to spot when cracks and defects in concrete will occur and to prevent them before they happen.

It also becomes easier to spot areas that are too weak for added weight for the time being. So contractors can avoid overloading them and causing a potentially hazardous worksite incident.

In Short, Maturix Helps Contractors Produce Structures with Better Quality

Maturix gives contractors the ability to glean accurate insight into their concrete’s development at a faster rate seamlessly. That gives them all they need to produce concrete structures efficiently with fewer defects, making Maturix not only a way to boost worksite efficiency but also a way to create better quality concrete.