Category

- Concrete Sensors

Over the past year or so, you’ve gotten to learn about our latest product, the Maturix® Smart Concrete® Sensors, and the benefits they offer. Throughout it all, you’ve probably heard us mention the maturity method once or twice. It’s a concept that our wireless concrete sensors leverage to improve the process of concrete monitoring. But what is it exactly?

To answer that, we’ve brought on Marina Salvador, the instructional designer for the creator of the Maturix® Sensors, Sensohive Technologies ApS. Read on to see her define the maturity method these sensors use, what the steps involved in this method are, and what you can do to learn more.

The Definition

The maturity method is a non-destructive test method that can be used to estimate the early-age strength development of concrete. The main assumption of the maturity method is that if two samples of the same concrete mix have the same maturity, they will also have the same strength, even if they were cured under different temperature conditions.

Thanks to new technologies and smart maturity systems like Maturix, which uses wireless temperature sensors and cloud computing, the maturity method is now a fast and easy method to use for real-time strength estimation.

The maturity method has three main steps, which you can read more about below.

Method Step 1: Make a Maturity Calibration

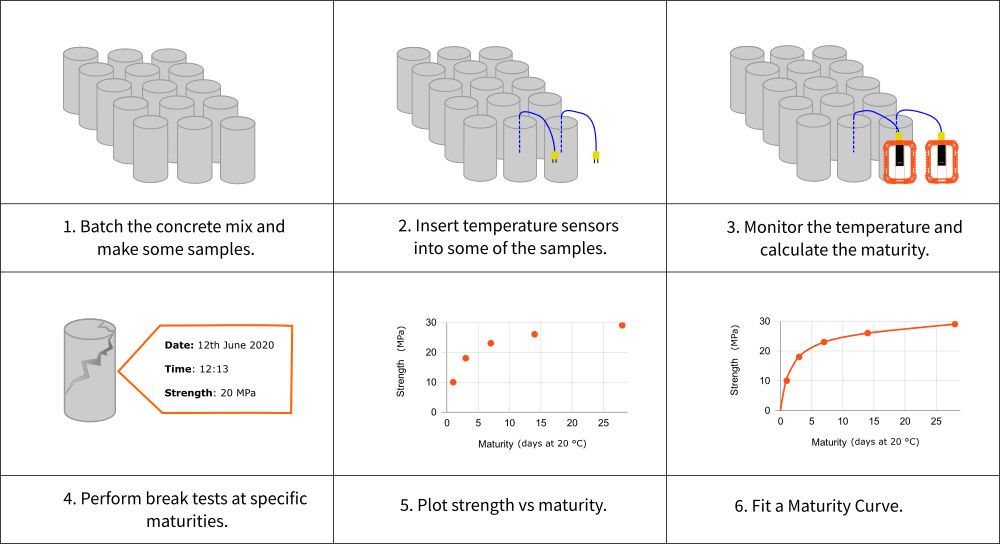

A maturity calibration determines the relationship between the maturity and strength development of a specific concrete mix.

To find this relationship, you make some samples with the concrete mixture that you will use in your project and instrument some of them with temperature sensors. The samples are then cured under the same conditions, and the temperature history is measured using the sensors. Then, you need to perform break tests of the samples at different test ages to determine their compressive strength. Once that is done, plot the strength data from the break tests and the maturity from the temperature history in a graph. Lastly, find the best-fitting curve through your data points, also known as the maturity curve.

Note: You can add the strength results and maturity values in Maturix, and the system will automatically plot the maturity curve.

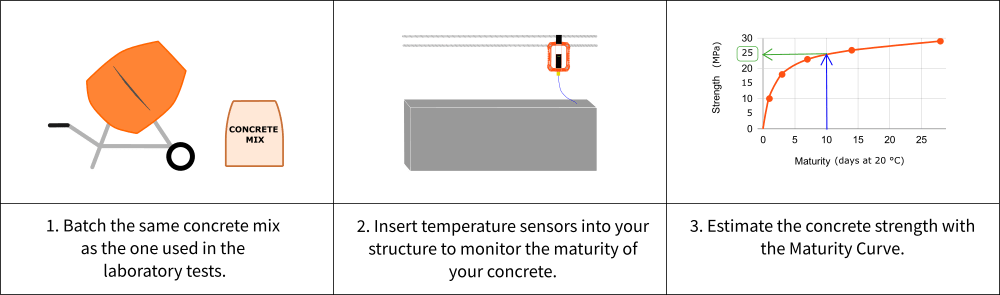

Method Step 2: Estimate the In-Place Strength

Once you have performed a maturity calibration for your concrete mixture, you can estimate the in-place concrete strength by placing temperature sensors inside your structure. These will calculate the maturity index in your concrete and relate it to a certain strength from the maturity curve.

Note: With Maturix, it is extremely easy to follow the strength development, as the software will display the results in real time, and these can be accessed remotely. Moreover, it is possible to set up alarms to get notified when the desired strength has been achieved.

Method Step 3: Validate the Maturity Calibration

Validating the calibration and maturity curve regularly is important because there might be small variations in materials, batching equipment, and conditions that might affect their accuracy.

To validate your maturity calibration, make some samples during the next batch and compare the strength estimated using the maturity method with the strength obtained from other testing methods.

ASTM C1074 strongly recommends not to perform critical operations without verification of the maturity calibration or without strength validation using other test methods.

Further Reading

To learn more about the three steps of the maturity method, we recommend you read these articles: “Maturity Calibration,” “Estimate In-place Strength with the Maturity Method,” and “Validating the Maturity Calibration.”